Beyond theory: Engineers hope nanotechnology can make hydrogen economy real

Scientists would never call theory the easy part, but to an engineer it is only the beginning. Nowhere on the national agenda is the dichotomy between theory and practice more apparent than with the so-called “Hydrogen Economy,” a future when seemingly limitless clean energy will be extracted through hydrogen-powered fuel cells. Politicians from the White House to the statehouse have made florid promises. It now falls to engineers to make it actually work. Just how might cars, for example, carry all their hydrogen fuel?

“There are two issues that are pushing the world toward using hydrogen as a fuel, and those are global warming and the fact that oil is a limited resource,” says materials science and engineering Professor Bruce Clemens. “But hydrogen storage is a huge problem. Right now there really is no good way to store it.”

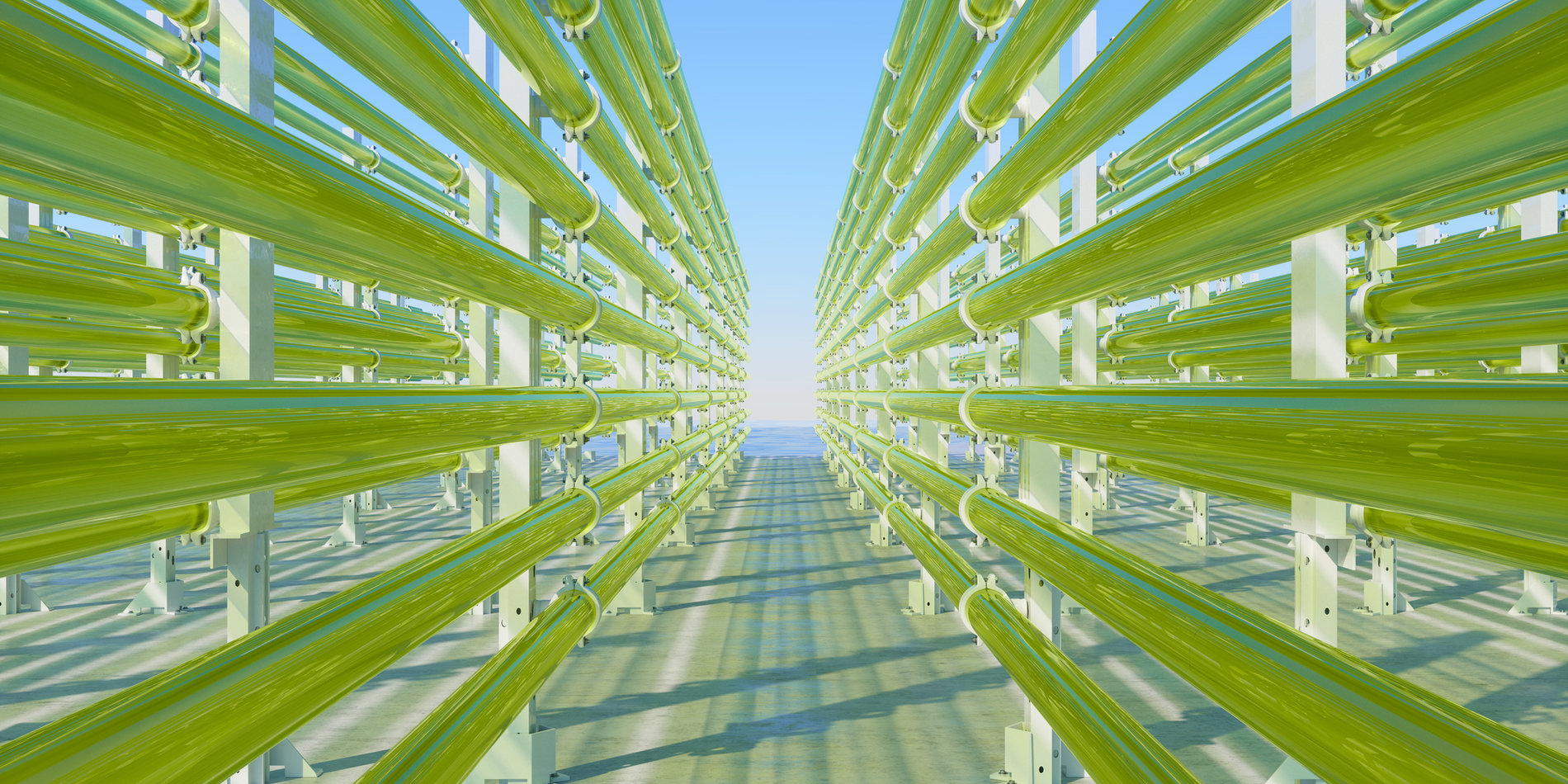

Clemens’s research group in collaboration those of Hongjie Dai, a chemistry professor, and Anders Nilsson, an associate professor at the Stanford Synchrotron Radiation Laboratory (SSRL), are working on a solution. Their approach is to use nanotechnology, in particular carbon nanotubes and palladium nanoparticles. It is a work in progress, but success would mean overcoming a tall hurdle on the way to making transportation environmentally sustainable.

Fussing about fuel

Through simple chemical reactions, fuel cells fed hydrogen and air yield only electricity, heat and water. Hydrogen is the most common element in the universe. But consider that at room temperature, it’s a gas. It is way too diffuse to carry around in this state. It must either be extremely compressed, cooled down until it becomes a liquid, or bonded with a chemical carrier.

Each of these ideas has its problems. Even after it is compressed under 200 times normal air pressure, the amount of hydrogen needed to drive 300 miles would still take up as much space as an oil drum. That’s a lot of volume for a passenger car to provide. Meanwhile, a tank rupture would result in a powerful explosion. Liquified hydrogen would take up less space, but there, too, a tank rupture could be dangerous and there is a significant energy cost to keep it cold.

Given the choices, Clemens likes the third option: storing hydrogen within a chemical medium. Other engineers have shown, for example, that hydrogen can be stored in a powdery material such as Magnesium Nickel Hydride (Mg2NiH4), but the hydrogen content is relatively low (only 3.6 percent by weight), hydrogen is released somewhat slowly, and the chemical breaks down when exposed to air. Still, the general idea of storing hydrogen within some solid medium could be safe and economical.

Testing tubes

The challenge is finding a suitable carrier with the maximum amount of hydrogen storage by weight. This means using a relatively light element. Carbon is only 12 times as heavy as hydrogen so if each carbon atom bonds with a hydrogen atom then carbon can store hydrogen up to 7.7 percent by weight. This would store twice as much hydrogen as Mg2NiH4 and be just as safe. So what kind of carbon container would achieve this theoretical maximum of carbon-hydrogen bonds? This answer is where nanotechnology comes in.

In early 2004, Clemens, Dai, Nilsson and former mechanical engineering Assistant Professor KJ Cho won funding from Stanford’s Global Climate and Energy Project to look into whether nanotubes–picture a chickenwire fence of carbon rolled up into a long thin tube–might be the answer.

Early theoretical calculations by Cho showed that while a flat sheet of carbon wouldn’t bond with hydrogen well at all, the proclivity for bonding would increase dramatically as the sheet was rolled up into a thin tube. In practice, however, researchers at many institutions realized that in experiments plain carbon nanotubes would store only a paltry 0.18 percent hydrogen by weight.

Just like in the big picture of the hydrogen economy, the focus shifted to the difficulty of closing the considerable gap between theory and practice.

A key advance came from Nilsson and student Anton Nikitin. Garden variety hydrogen gas comes in molecular form, where two hydrogen atoms are bonded together. The researchers reasoned that carbon-hydrogen bonds might form more readily if they exposed nanotubes to separate hydrogen atoms. What Nilsson and Nikitin found is that under the right lab conditions, atomic hydrogen will indeed produce the one-to-one carbon and hydrogen bonds that achieve the theoretical maximum of 7.7 percent hydrogen by weight.

The work was encouraging, but real-world use in a car rather than a lab requires finding a practical means of splitting molecular hydrogen into atomic hydrogen. This has to be feasible at the temperatures and pressures that are safe in a car.

Metal magic

“Our work took the next step,” Clemens says. “We said let’s see if we can use a catalyst to break the molecular bond in hydrogen molecules and have catalyst nanoparticles placed on the nanotubes to act as an atomic hydrogen source.”

Clemens and then student Yong-Won Lee (PhD 2006 MSE) started working on lacing the nanotubes with tiny particles of metal–a process called “doping”–to see what happened. Using a variety of doping techniques they experimented with both platinum and palladium.

What they have found is that by sputter-depositing palladium (using ions like cue balls to knock palladium atoms out of a solid and onto the nanotubes) they can quadruple the tubes’ hydrogen storage capacity to 0.72 percent by weight. This is still about a tenth as good as theory and only a fifth as good as Mg2NiH4 but the chase isn’t over.

“This process works,” Clemens says. “Now we just have to optimize it.”

The problem is that the hydrogen atoms just aren’t settling far enough from the palladium nanoparticles. Once the carbon atoms in the immediate neighborhood have all bonded with a corresponding hydrogen atom, the area becomes saturated. The next phase of the research will be to find ways to get the hydrogen to spread out further–to move to unsettled land, so to speak. Ideas include soaking tubes in a solution of hydrogen ions or simply increasing the temperature of the process so that the hydrogen atoms are more jittery.

“If we got to 8 percent and had good kinetics and thermodynamics for the storage and release of hydrogen, we’d have the best available technology for hydrogen storage,” Clemens says. And that could bring the hydrogen economy a lot closer to reality.