Our last car, Arctan, was designed for the Challenger vehicle class of the World Solar Challenge. It seats one driver and is equipped with a push-button turn-on system, LED headlights, regenerative braking and other features of a modern electric car. Although it looks sleek, the solar car contains few luxuries. Nearly every component either generates power or helps the car move from point A to point B.

Every two years, our team competes in the premier World Solar Challenge in Australia. We’re building a new car right now that we’ll unveil this summer in time for the competition. The race is amazing – it’s 3,000km across the desert, the flat roads and constant sunlight of the Australian Outback. There’s no other place quite like it for a solar car race.

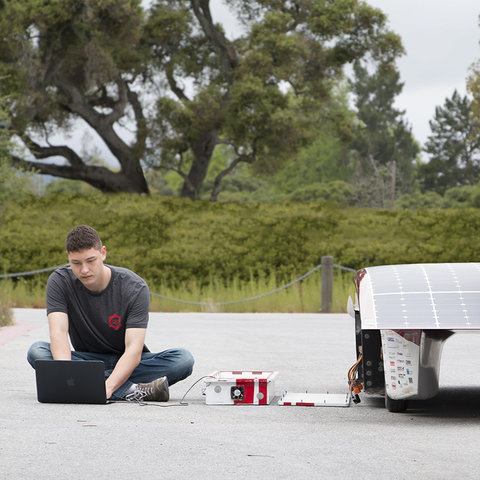

Our team takes pride in building as much of the car as possible ourselves. This sets us apart from many of the top teams we compete against. We design everything from the printed circuit boards, which manage the car’s battery pack and driver controls, to mechanical components like the suspension, chassis and roll cage, which must be strong, lightweight and fit within tight constraints. We perfect the car’s aerodynamic shape through months of computational fluid dynamics simulation, then spend spring break laying up carbon fiber composite materials into fiberglass molds to create the car body. We also manufacture our car’s solar array, first determining the optimal module configuration through solar simulation, then soldering individual silicon solar cells into modules, and finally laminating the array in a high-performance protective material. We construct the entire car during our 13-month build cycle. Our workshop is empty when the race regulations are released in June and contains a brand-new homemade solar car the following July.

The race gives us an opportunity to solve problems in a variety of unique circumstances. When we’re here at Stanford, we’re at home. It’s easy to solve problems because we have all the tools that we need in our garage space. But when we’re on the side of the road in the middle of the Outback or in a town with a population of five people, we’re forced to become creative and resourceful.

Related spotlights

Thomas Colburn

Kayla Patterson